Masero anotakura zvinhu ndiwo anonyanya kukosha muhuremu system.Kunyange zvazvo achiwanzoremerwa, achiita sesimbi yakasimba, uye akanyatsogadzirwa kuti areme makumi ezviuru zvemapaunzi, masero ekutakura zvinhu chaizvo zvinotapukira.Kana yakaremerwa, iko kurongeka kwayo uye kutendeseka kwechimiro kunogona kukanganiswa.Izvi zvinosanganisira welding pedyo nemitoro maseru kana pahuremu chimiro pachayo, senge silo kana mudziyo.

Welding inoburitsa macurrents akakwira kupfuura anotakura maseru anowanzo kuisirwa.Pamusoro pekuratidzwa kwemagetsi ikozvino, welding inofumurawo sero rekutakura kune tembiricha yakakwira, weld spatter, uye mechaniki kuwandisa.Mawaranti mazhinji evagadziri vemasero haavhare kukuvara kwesero nekuda kwekutengesa pedyo nebhatiri kana vakasiiwa munzvimbo.Nokudaro, zvakanakisisa kubvisa masero emutoro asati atengesa, kana zvichibvira.

Bvisa Load Cells Before Soldering

Kuti uone kuti welding haikuvadzi mutoro wako sero, ibvise usati waita chero welding kune chimiro.Kunyangwe iwe usiri solder padhuze nekutakura maseru, ichiri kukurudzirwa kubvisa ese anotakura maseru asati atengesa.

Tarisa kubatanidza magetsi uye kugadzika mukati mehurongwa.

Dzima midziyo yese yemagetsi pachimiro.Usambofa weld pane inoshanda kuyera zvivakwa.

Bvisa chisero chekutakura kubva kune zvese zvinongedzo zvemagetsi.

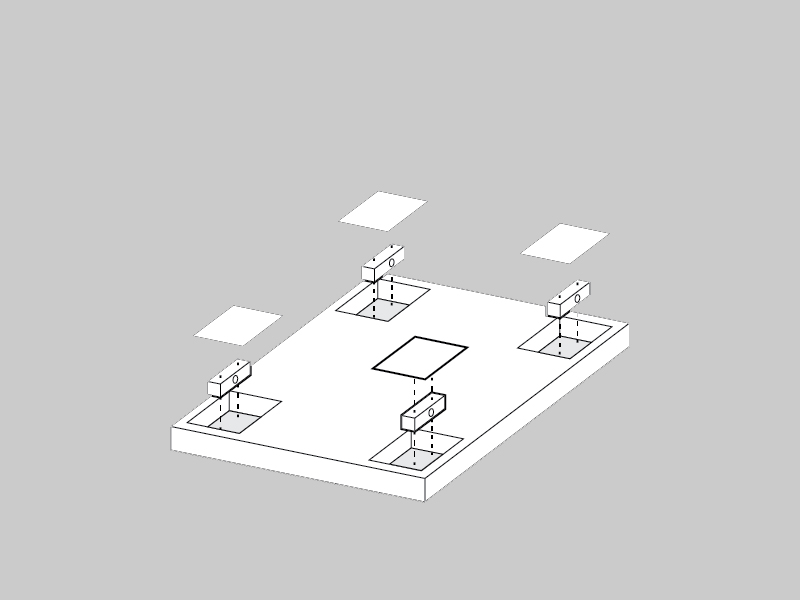

Ita shuwa kuti uremu module kana gungano rakachengetedzwa zvakachengeteka kune chimiro, wobva wabvisa zvakachengeteka sero yekuremerwa.

Isa ma spacers kana dummy mutoro maseru munzvimbo yavo mukati mewelding process.Kana zvichidikanwa, shandisa hoist yakakodzera kana jack pane yakakodzera jacking point kuti usimudze zvakachengetedzeka chimiro kubvisa mutoro maseru uye kutsiva iwo nema dummy sensors.Tarisa iyo mechanical assembly, wobva wanyatsoisa chimiro kumashure pamusangano wekuyera ne dummy bhatiri.

Ita shuwa kuti nzvimbo dzese dzekukuchidzira dziripo usati watanga basa rewelding.

Mushure mekunge soldering yapera, dzorera sero yekutakura kugungano rayo.Tarisa mechanical kutendeseka, batanidza zvakare midziyo yemagetsi uye batidza simba.Scale calibration inogona kudikanwa panguva ino.

Soldering apo mutoro cell haugoni kubviswa

Kana zvisingabviri kubvisa sero yekuremerwa isati yaiswa welding, tora matanho anotevera kuchengetedza uremu system uye kuderedza mukana wekukuvara.

Tarisa kubatanidza magetsi uye kugadzika mukati mehurongwa.

Dzima midziyo yese yemagetsi pachimiro.Usambofa weld pane inoshanda kuyera zvivakwa.

Bvisa chisero chekutakura kubva kune zvese zvinongedzo zvemagetsi, kusanganisira bhokisi rejunction.

Rongedza sero rinotakura kubva pasi nekubatanidza inopinza uye inobuda inotungamira, wobva wavharira nhovo inotungamira.

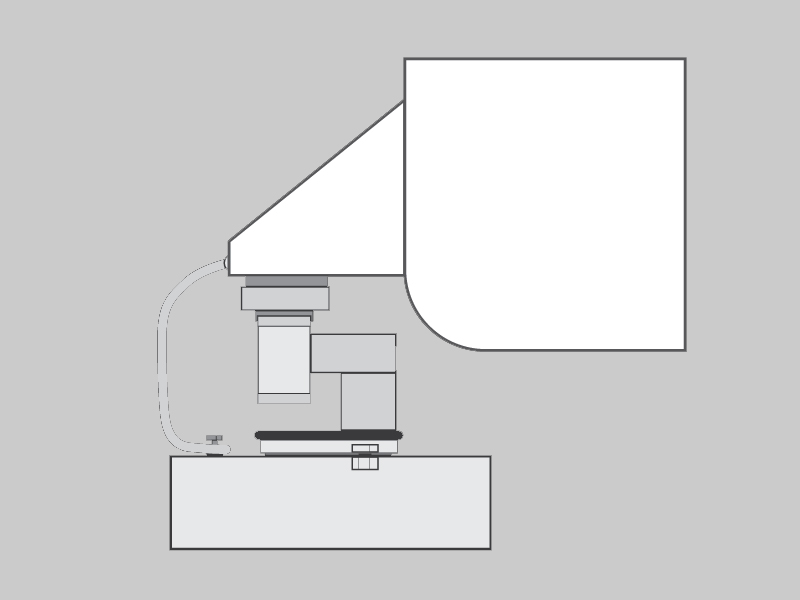

Isa tambo dzebypass kuderedza kuyerera kwezvino kuburikidza nesero rinotakura.Kuti uite izvi, batanidza iyo yepamusoro yekuremedza sero gomo kana gungano kune yakasimba pasi uye woimisa nebhaudhi kune yakaderera kuramba kubata.

Ita shuwa kuti nzvimbo dzese dzekukuchidzira dziripo usati watanga basa rewelding.

Kana nzvimbo ichibvumira, isa nhovo kuchengetedza mutoro sero kubva kupisa uye welding spatter.

Ziva nezve mechanic kuwandisa mamiriro uye tora matanho ekuzvidzivirira.

Ramba welding padhuze nemaseru ekuremerwa kusvika padiki uye shandisa iyo yepamusoro amperage inotenderwa kuburikidza neAC kana DC weld yekubatanidza.

Mushure mekunge soldering yapera, bvisa iyo mutoro cell bypass tambo uye tarisa kutendeseka kwemakanika kweyekuremerwa sero gomo kana kusangana.Batidzazve midziyo yemagetsi wobatidza simba.Scale calibration inogona kudikanwa panguva ino.

Usaite solder mutoro masero magungano kana kuyera modules

Usambofa wakatengesa zvakananga mutoro sero magungano kana kuyera mamodule.Kuita izvi kunobvisa zvese waranti uye kukanganisa kurongeka uye kuvimbika kwehuremu system.

Nguva yekutumira: Jul-17-2023